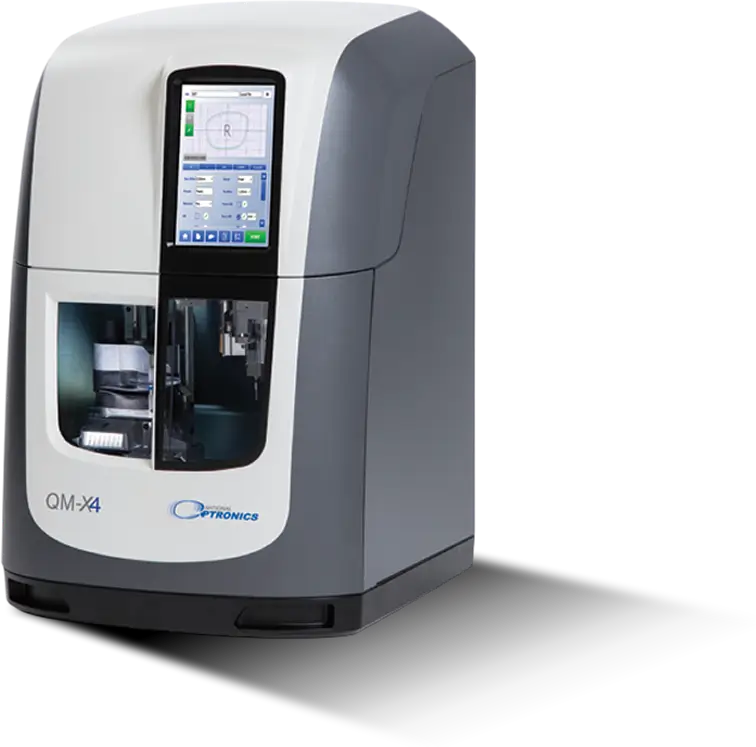

LENS EDGER

The QM-X4 is a tabletop edger that expands your in-house lens finishing abilities by processing lenses with complex shapes, shelving, milling, and drilling. It’s a robust edger, compact and user-friendly package that’s backed by the industry-leading engineering and service teams at National Optronics and National Optronics.

Featuring 4 Major Enhancements

Faster Processing

- Integrated diamond blade design of the main tool reduces need for frequent blade changes

- Software enhancements related to toolpath algorithms allow improved cycle times and processing

Improved Surface Finish Quality

- High-luster finish on polished lenses

Machine Reliability

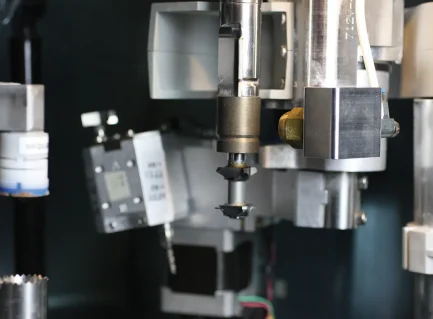

- Redesigned 4th-axis spindle for drilling, milling, and shelving improves reliability

- Added protection to the electrical cabling eliminates wear

- Internal covers on major mechanical components provide durability and dust protection

Safety Features

- Improved safety interlock system from mechanical switches to magnetic switches improve reliability, performance and operator safety

QM-X4

Green Operation

Environmentally friendly dry edging saves water and makes lens debris clean-up easy.

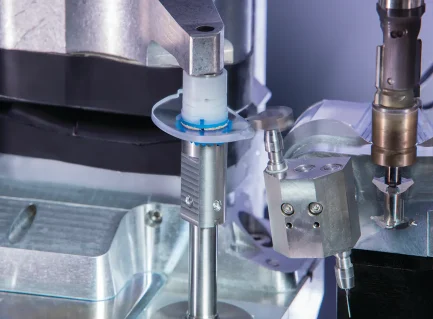

Innovative Tooling

A fixed dual diamond blade design eliminates the need to frequently change blades and improves productivity and lens edge quality.

Remote Diagnostics

An easy-to-use remote diagnostics system provides fastest response times for immediate technical support and current software updates.

Working Range

- Front base curves: up to 10 dpt

- Minimum finishing B size with standard clamping assembly: 21 mm rimless; 23- mm bevel

- Lens diameter: max. 85 mm (effective)

- Materials: all organic lens materials; i.e. CR-39;

- Hi-Index; Polycarbonate; Trivex

Communications

- VCA/DCS compatible

- Stand alone

Additional Features

- Small footprint saves valuable counter space.

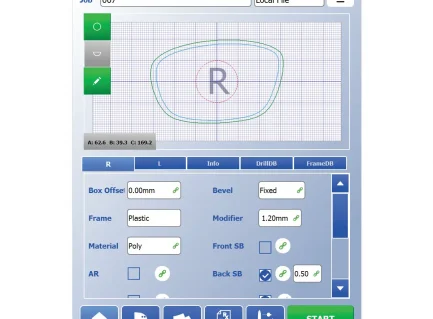

- Easy touch-screen operation with user-friendly interface.

- Inherently low torque cutting process minimizes risk of lens slippage.

- Service friendly: all components are easily accessible.

Facilities

- Energy requirements: 100-240V, 50-60Hz 1 phase, 350 Watts

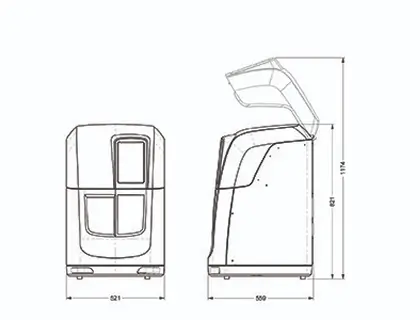

- Dimensions (wxdxh): 21 x 22 x 32 inches 521 x 559 x 821 mm

- Weight: 180 lb

Options

- Lens shelving at various depths as well as in partial areas around the lens for easy processing of complex finishing jobs, e.g. on fashionable sports frames.

- Variable angle drilling provides better cosmetics and easier mounting for a variety of base curves and prescriptions.

- Frame editor software allows editing existing trace files or creating new complex designs quickly and efficiently.

- Cabinet: 3”w x 28.8”d x 34.3”h